2009 CORVETTE ZR1

POWERED BY THE MOST POWERFUL PRODUCTION ENGINE EVER

FROM GM: THE SUPERCHARGED LS9 SMALL-BLOCK V-8

When

it arrives next summer, the 2009 Chevrolet Corvette

ZR1 will be the most powerful and fastest production

car ever produced by General Motors, with

performance enabled by a new, supercharged 6.2L LS9

small-block V-8 engine.

When

it arrives next summer, the 2009 Chevrolet Corvette

ZR1 will be the most powerful and fastest production

car ever produced by General Motors, with

performance enabled by a new, supercharged 6.2L LS9

small-block V-8 engine.

Incorporating the engineering experience already

found in the Corvette Z06’s LS7 engine and the

new-for-2008 6.2L LS3 of the Corvette, GM Powertrain

is targeting 100 horsepower per liter for the LS9,

or 620 horsepower (462 kW), and approximately 595

lb.-ft. of torque (807 Nm); final SAE-certified

power levels will be available in early March 2008.

It is,

indeed, the ultimate small-block engine for the

ultimate Corvette.

“When you

experience the LS9 in the Corvette ZR1, the terms

performance and refinement take on a new meaning,”

said Tom Stephens, group vice president for GM

Powertrain and Quality. “The LS9 demonstrates an

outstanding performance range, with smooth

driveability at low speeds, and surprisingly fierce

performance when the customer wants more power.”

The

enabler of the LS9’s performance is a new, large

positive-displacement Roots-type supercharger – with

a unique four-lobe design – developed for the engine

by Eaton. It is teamed with an integrated charge

cooling system that reduces inlet air temperature

for maximum performance. The LS9 represents the

first of several new, supercharged small-block

engines that will be introduced in GM vehicles in

the near future, each using superchargers of similar

design.

“The

small-block V-8 once again demonstrates it boundless

horsepower potential, versatile design and an

architecture with proven quality, durability and

reliability,” said Stephens. “We haven’t yet

realized the small-block’s performance potential.”

Performance

range

Performance

range

More than

just its tremendous peak horsepower and torque

numbers, the supercharged LS9 makes big power at

lower rpm and carries it in a wide arc to 6,600 rpm.

GM Powertrain testing shows the engine makes

approximately 300 horsepower (224 kW) at 3,000 rpm

and nearly 320 lb.-ft. of torque (434 Nm) at only

1,000 rpm. Torque tops 585 lb.-ft. (793 Nm) at about

the 4,000-rpm mark, while horsepower peaks at 6,500

rpm. The engine produces 90 percent of peak torque

from 2,600 rpm to 6,000 rpm.

Heavy-duty and lightweight reciprocating components

enable the engine’s confident high-rpm performance,

while the large-displacement Eaton supercharger

pushes enough air to help the engine maintain power

through the upper levels of the rpm band.

“The

sixth-generation design of the supercharger expands

the ‘sweet zone’ of the compressor’s effectiveness,

broadening it to help make power lower in the rpm

band,” said Ron Meegan, assistant chief engineer.

“To put it simply, the low-end torque is amazing.”

The LS9

is assembled by hand at GM’s Performance Build

Center, a unique, small-volume engine production

facility in Wixom, Mich., that also builds the

Corvette Z06’s LS7 engine and other high-performance

GM production engines.

Cylinder block and reciprocating assembly details

The

LS9’s aluminum cylinder block features steel,

six-bolt main bearing caps, with enlarged vent

windows in the second and third bulkheads for

enhanced bay to bay breathing. Cast iron cylinder

liners – measuring 4.06 inches (103.25 mm) in bore

diameter – are inserted in the aluminum block and

they are finish-bored and honed with a deck plate

installed. The deck plate simulates the pressure and

minute dimensional variances applied to the block

when the cylinder heads are installed, ensuring a

higher degree of accuracy that promotes maximum

cylinder head sealing, piston ring fit and overall

engine performance.

The

LS9’s aluminum cylinder block features steel,

six-bolt main bearing caps, with enlarged vent

windows in the second and third bulkheads for

enhanced bay to bay breathing. Cast iron cylinder

liners – measuring 4.06 inches (103.25 mm) in bore

diameter – are inserted in the aluminum block and

they are finish-bored and honed with a deck plate

installed. The deck plate simulates the pressure and

minute dimensional variances applied to the block

when the cylinder heads are installed, ensuring a

higher degree of accuracy that promotes maximum

cylinder head sealing, piston ring fit and overall

engine performance.

Nestled

inside the cylinder block is a forged steel

crankshaft that delivers the LS9’s 3.62-inch (92 mm)

stroke. It features a smaller-diameter

ignition-triggering reluctor wheel and a nine-bolt

flange – the outer face of the crankshaft on which

the flywheel is mounted – that provides more

clamping strength. Other non-supercharged 6.2L

engines, such as the base Corvette’s LS3, have a

six-bolt flange. A torsional damper mounted to the

front of the crankshaft features a keyway and

friction washer, which also is designed to support

the engine’s high loads.

Attached

to the crankshaft is a set of titanium connecting

rods and forged aluminum pistons, which, when

combined with the cylinder heads, delivers a 9.1:1

compression ratio. This combination is extremely

durable and lightweight, enabling the LS9’s high-rpm

capability.

Cylinder head details

The basic

cylinder head design of the LS9 is similar to the

L92-type head found on the LS3 V-8, but it is cast

with a premium A356T6 alloy that is better at

handling the heat generated by the supercharged

engine – particularly in the bridge area of the

cylinder head, between the intake and exhaust

valves.

In

addition to the special aluminum alloy, each head is

created with a rotocast method. Also known as spin

casting, the process involves pouring the molten

alloy into a rotating mold. This makes for more even

distribution of the material and virtually

eliminates porosity – air bubbles or pockets trapped

in the casting – for a stronger finished product.

In

addition to the special aluminum alloy, each head is

created with a rotocast method. Also known as spin

casting, the process involves pouring the molten

alloy into a rotating mold. This makes for more even

distribution of the material and virtually

eliminates porosity – air bubbles or pockets trapped

in the casting – for a stronger finished product.

Although

the heads are based on the L92 design, they feature

swirl-inducing wings that are cast into the intake

ports. This improves the mixture motion of the

pressurized air/fuel charge. The charge enters the

combustion chambers via titanium intake valves that

measure 2.16 inches (55 mm) in diameter. Spent gases

exit the chambers through 1.59-inch (40.4 mm) hollow

stem sodium-filled exhaust valves. The titanium

intake and sodium-filled exhaust valves are used for

their lightweight and high-rpm capability.

To ensure

sealing of the pressurized engine, unique,

four-layer steel head gaskets are used with the

LS9’s heads.

Camshaft and valvetrain

The broad

power band enabled by the LS9’s large-displacement

supercharger allows it to make strong low-end torque

and great high-rpm horsepower, which allowed

engineers to specify a camshaft with a relatively

low lift of 0.555-inch (14.1 mm) for both the intake

and exhaust valves. This low-overlap cam has lower

lift and slower valve-closing speeds than the Z06’s

505-horsepower (377 kW) LS7, helping the LS9 – with

its approximately 620 horsepower – deliver exemplary

idle and low-speed driving qualities.

The

camshaft actuates a valvetrain that includes many

components, including the lifters, rocker arms and

valve springs, of the LS3 engine. However, LS7

retainers are used to support the engine’s high-rpm

performance.

Supercharger and charge cooler details

The LS9’s

R2300 supercharger is a sixth-generation design from

Eaton, with a case that is specific to the Corvette

application. The supercharger features a new

four-lobe rotor design that promotes quieter and

more efficient performance, while its large,

2.3-liter displacement ensures adequate air volume

at high rpm to support the engine’s high-horsepower

aspiration. Maximum boost pressure is 10.5 psi (0.72

bar).

The

supercharger is an engine-driven air pump that

contains a pair of long rotors that are twisted

somewhat like pretzel sticks. As they spin around

each other, incoming air is squeezed between the

rotors and pushed under pressure into the engine –

forcing more air into the engine than it could draw

under “natural” aspiration. The rotors are driven by

a pulley and belt that are connected to the engine’s

accessory drive system.

The

supercharger is an engine-driven air pump that

contains a pair of long rotors that are twisted

somewhat like pretzel sticks. As they spin around

each other, incoming air is squeezed between the

rotors and pushed under pressure into the engine –

forcing more air into the engine than it could draw

under “natural” aspiration. The rotors are driven by

a pulley and belt that are connected to the engine’s

accessory drive system.

Because

the pressurized air is hotter than naturally

aspirated air, the LS9 employs a liquid-to-air

charge cooling system to reduce inlet air

temperature after it exits the supercharger –

reducing the inlet air temperature by up to 60

degrees C (140 F). Cooler air is denser and allows

the engine to make the most of its high-pressure air

charge. The charge cooling system includes a

dedicated coolant circuit with a remote-mounted pump

and reservoir.

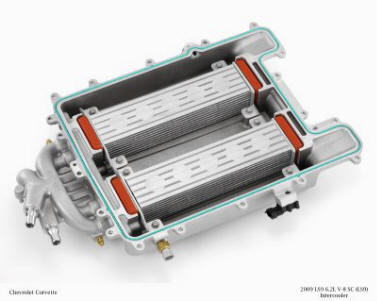

The

design of the supercharger case and its integrated

charge cooling system was driven by the space and

dimensions afforded under the Corvette’s hood. To

that end, the charge cooler was designed as a “dual

brick” system, with a pair of low-profile heat

exchangers mounted longitudinally on either side of

the supercharger. Coupled with the supercharger

itself, this integrated design mounts to the engine

in place of a conventional intake manifold and is

only slightly taller than a non-supercharged 6.2L

engine. The air inlet and rotor drive pulley are

positioned at the front of the supercharger.

Additional engine details

Oiling system: The LS9 uses a dry-sump

oiling system that is similar in design to the LS7’s

system, but features a higher-capacity pump to

ensure adequate oil pressure at the higher cornering

loads the ZR1 is capable of achieving. An oil-pan

mounted oil cooler is integrated, too, along with

piston-cooling oil squirters located in the cylinder

block. The expanded performance envelope of the

Corvette ZR1 required changes to the dry sump system

also used in the Z06. System capacity is increased

and scavenge performance improved to meet the

demands of Chevrolet's highest-performance sportscar.

Water pump: To compensate for the heavier

load generated by the supercharger drive system, an

LS9-specific water pump with increased bearing

capacity is used.

Accessory drive system: To package the

accessory drive system in the Corvette’s engine

compartment, the supercharger drive was integrated

into the main drive system. This required a wider

11-rib accessory drive system to be used with the

LS9 in order to support the load delivered by the

supercharger.

Fuel system: The LS9 uses high-capacity

48-lb./hr. fuel injectors with center-feed fuel

lines. The center feed system ensures even fuel flow

between the cylinders with less noise. In order to

ensure fuel system performance during low speed

operation as well as under the extreme performance

requirements of wide open throttle (WOT), a dual

pressure fuel system was developed. This system

operates at 250 kPa at idle and low speed, and

ratchets up to 600 kPa at higher-speed and WOT

conditions.

Throttle body: An 87-mm, single-bore

throttle body is used to draw air into the engine.

It is electronically controlled.

Rocker covers / ignition coils: Unique

rocker covers with new, direct-mount ignition coils

are used. Other Gen IV engines, such as the LS3,

feature coil packs mounted to a bracket. The LS9’s

direct-mounted coils offer a cleaner appearance and

a shorter lead between the coil and spark plug.

Beauty cover: A special engine cover is

attached to the top of the LS9. It surrounds the

intercooler, which is visible through a hood window.

The intercooler has the legend “LS9 SUPERCHARGED”

embossed on the left and right sides, and the engine

beauty cover features the Corvette crossed flags

logo debossed at the front.

New six-speed manual transmission

The

Corvette ZR1’s LS9 engine is backed by a Tremec

TR6060 six-speed manual transmission, with a

twin-disc clutch system. It is based on the

new-for-2008 TR6060 six-speed, but upgraded to

handle the LS9’s torque output and delivers improved

shift quality.

The

Corvette ZR1’s LS9 engine is backed by a Tremec

TR6060 six-speed manual transmission, with a

twin-disc clutch system. It is based on the

new-for-2008 TR6060 six-speed, but upgraded to

handle the LS9’s torque output and delivers improved

shift quality.

The

twin-disc clutch system provides exceptional

clamping power, while maintaining an easy clutch

effort. The system employs a pair of 260-mm discs,

which spreads out the engine’s torque load over a

wider area, enabling tremendous clamping power to

channel the LS9’s torque. It also dissipates heat

better and extends the clutch life (in normal

driving).

Thanks to

comparatively small plates, the twin-disc system

enables similar disc inertia to the Corvette Z06,

which has a 290-mm single-disc system, contributing

to low shift effort and providing exceptionally

smooth engagement and light pedal effort. In fact,

the more powerful ZR1 has a pedal effort similar to

the Z06.

ZR1-specific gearing in the transmission provides a

steep first-gear ratio that helps launch the car.

The car’s top speed is achieved in sixth gear – a

change from the fifth-gear top-speed run-outs in the

manual transmission Corvette and Corvette Z06. The

gears also are designed to balance performance with

refinement. The angles of the gear teeth are

optimized to provide both strength and quietness.

Next - -

>